Stellar Work Construction

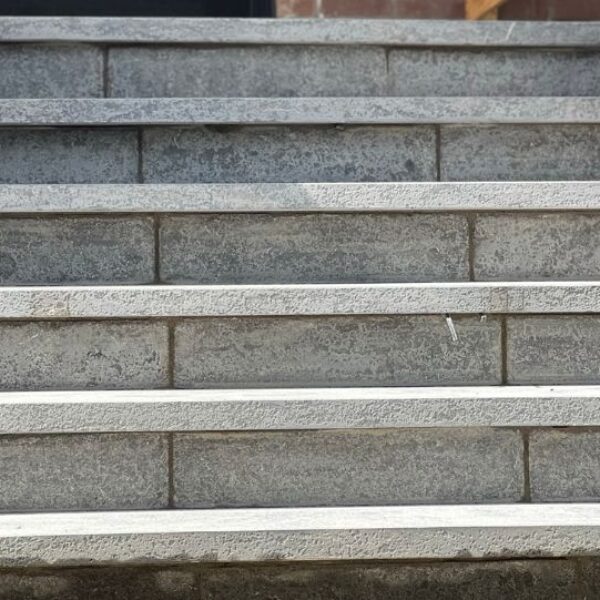

Hardscaping & interlocking

Home » Exterior Renovation » Hardscaping & Interlocking

Our Hardscaping & Interlocking Services

Hardscaping extends beyond just interlocking pavers to include various structural elements in outdoor spaces:

- Retaining Walls: Useful for managing slopes and creating level areas.

- Outdoor Kitchens: Incorporating cooking and dining areas into the landscape.

- Fire Pits: Adding warmth and ambiance to outdoor living spaces.

- Water Features: Such as fountains or ponds, enhancing the sensory experience of the landscape.

- Pergolas and Gazebos: Providing shade and structure to outdoor areas.

Interlock Installation Process

- Design and Planning

- Choose a design pattern that fits your needs, area, color, and style preferences

- Determine the project area and required materials

- Ensure proper drainage planning with a 1/8-1/4 inch drop per foot

- Site Preparation

- Clear and excavate the area to a depth of 2-10 inches below existing grade, depending on usage

- Mark utilities and ensure safety measures are in place

- Base Preparation

- Fill the excavated area with baserock

- Level and compact the base material

- For pedestrian traffic: 3-4 inches of compacted base

- For vehicular traffic: 12-14 inches of compacted base

- For heavy vehicles: 22-24 inches of compacted base

- Edge Restraint Installation

- Install a stable edge restraint to prevent lateral movement of pavers and sand bedding

- Options include existing hard edges, vinyl molded restraints, or concrete restraints

- Sand Bedding

- Spread a 1-inch layer of clean, sharp concrete sand as a bedding course

- Level the sand using screed pipes and a straight edge

- Laying Pavers

- Start at a 90-degree corner or use a pre-set string as a guide

- Place pavers flat on the sand bed, working in a forward motion

- Follow the chosen pattern layout, checking frequently for accuracy

- Use a masonry saw to cut pavers as needed for edges and corners

- Initial Compaction

- Spread a light layer of sand over the laid pavers

- Use a vibrating plate compactor to begin the interlocking process

- Joint Filling

- Spread dry paver joint or masonry sand over the surface, about 1/4 inch deep

- Use the vibrating plate compactor to work the sand into the joints

- Repeat the process 2-3 times to ensure joints are completely filled

- Final Compaction and Cleaning

- Make a final pass with the vibratory compactor

- Sweep off excess sand

- Optional Sealing

- Apply a sealer to protect pavers from stains and stabilize joint sand (if desired)

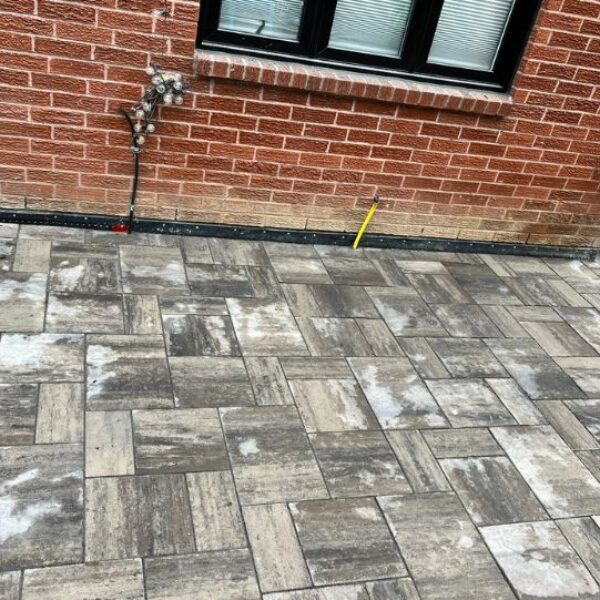

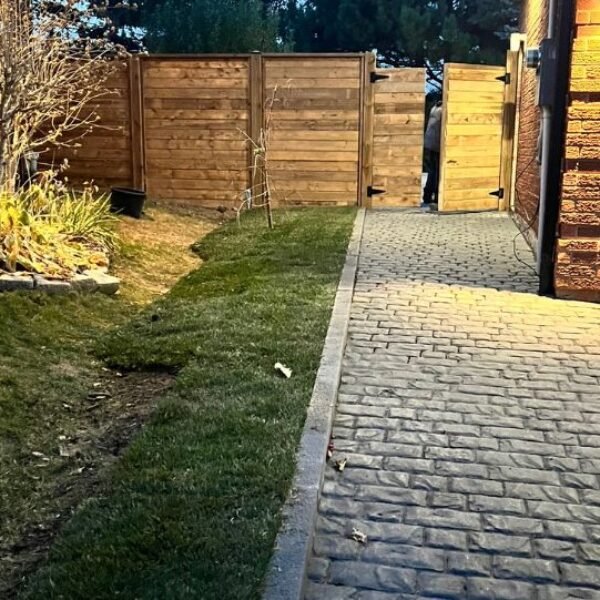

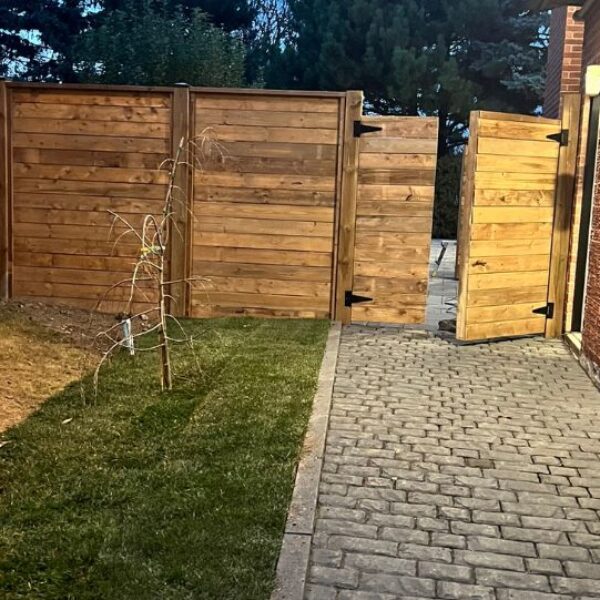

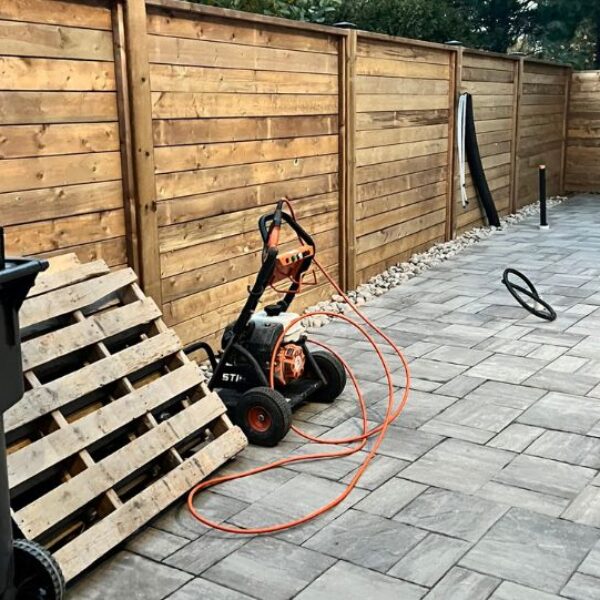

Our projects Gallery